Atlantic -33

Non-Tempering Steel

ATLANTIC 33 NON-TEMPERING STEEL Is a new departure alloy steel, relatively low in carbon. The steel combines hardness and tougl1noss with 11eat and fatigue resistance. It is made in the electric furnace from selected materials with expert care and supervision. Continued and painstaking research makes ATLANTIC 33 NON-TEMPERING STEEL more economical and more efficient.

EASIER TOOL MAKING

• Drawing of temper to suit different requirements Is unnecessary and completely eliminated.

• May be heated repeatedly at higher temperatures without altering its properties.

• Suitable hardness is obtained by merely heating the tool and quenching it in water.

• May be heated to almost a melting heat without danger of distortion.

• May be heated with an acetylene torch if desired, where regular facilities are not available.

• Possibility of overheating or burning the steel reduced to a minimum.

• Forged easily and welds readily to itself and other steels.

• Time is saved by eliminating the tempering operation.

LONGER-WEARING, MORE EFFICIENT TOOLS

• Tools made from ATLANTIC 33 NON-TEMPERING STEEL withstand concussion far beyond that of ordinary tool steels.

• Tools bite into and penetrate the hardest materials under continued shock without noticeable indentation on the cutting edge.

• Tools may be reground and resharpened often without the necessity of reforging.

WORKING INSTRUCTIONS

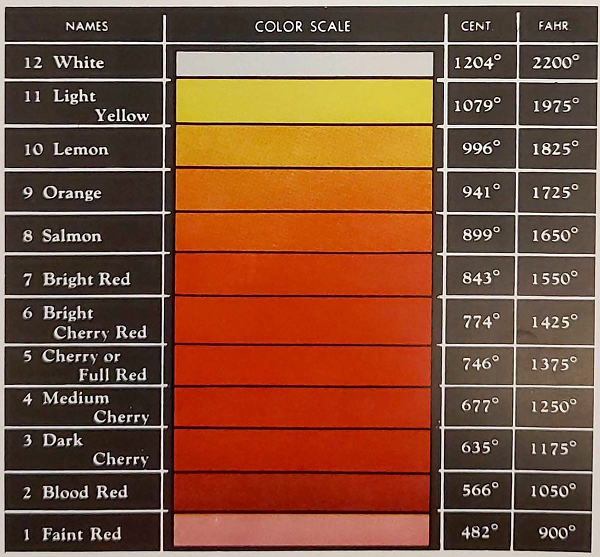

TO FORGE: Heat Slowly and uniformly to a temperature of about 1825 °F. to 1975 °F (lemon to yellow) and forge.

TO HARDEN: Reheat the cutting edge about 1" back between 1650°F. to 1950 °F. (salmon to lemon color) depending on hardness required. Quench in clean cold water.

DO NOT DRAW TEMPER